Zauważyłeś kiedyś produkt z niewłaściwą etykietą? Może to się zdarzyć z maszynami, które oznakowują przedmioty. Maszyny te powinny drukować odpowiednią etykietę na każdym przedmiocie, ale nie zawsze są w stanie to zrobić. Kiedy tak się stanie, trzeba będzie naprawić problem.

Gdy zauważysz, że etykieta używana na Twoich produktach jest nieprawidłowa, należy natychmiast zatrzymać maszynę. Sprawdź rolkę z etykietami i zobacz, czy zawiera odpowiednie etykiety. Czasami do prawidłowej partii trafiają nowe, błędne etykiety, co powoduje, że maszyna oznacza przedmiot niepoprawnie. Pomódl się do maszyny i załaduj do niej właściwe etykiety (czyli te, które według Ciebie są potrzebne), zanim ponownie ją włączysz i będziesz się modlić, by wszystko zadziałało.

Rozwiązywanie problemów z zapychaniem się etykiet

Wymień kilka typowych problemów występujących w maszynach do naklejania etykiet Zapchanie etykiety: Zapchanie etykiety to częsty problem w maszynach do naklejania etykiet. Zacinające się etykiety mogą prowadzić do opóźnień i błędów. Oto kroki, które możesz wykonać, aby rozwiązać problem z zapychaniem się etykiet:

Usiądź przed maszyną i wyłącz ją.

Delikatnie otwórz aplikator etykiet.

Sprawdź, czy możesz znaleźć jakieś przyklejone etykiety i ostrożnie je usunąć.

Spojrzeć na rolkę z etykietami — możesz zauważyć rozerwania lub zagniecenia, które najprawdopodobniej spowodowały zacięcie.

Włóż rolkę z etykietami i zabezpiecz aplikator.

Wykonaj ponownie konfigurację maszyny i sprawdź jej działanie na kilku produktach.

Problemy z wyrównaniem na maszynach do naklejania etykiet oraz sposoby ich rozwiązywania

Innym rodzajem problemu, który czasem występuje, jest problem z wyrównaniem. Etykiety proste, umieszczone centralnie na produktach, wyglądają estetycznie; jeśli są pochyłe i nie wyśrodkowane, opakowania będą wyglądały niechlujnie. Aby rozwiązać problemy z wyrównaniem maszyny do naklejania etykiet, wykonaj następujące czynności:

Wyłącz maszynę i zatrzymaj ją.

Ponieważ wiesz, że to musi zostać zrobione, upewnij się, że głowica aplikatora etykiet jest prawidłowo wyśrodkowana.

Upewnij się, że rolka z etykietami jest prawidłowo wyrównana i skoryguj ją w razie potrzeby.

Uruchom ponownie maszynę i przeprowadź próbę z kilkoma produktami, aby sprawdzić, czy jest prawidłowo wyrównana.

Komunikacja błędów pomiędzy drukarką a maszyną

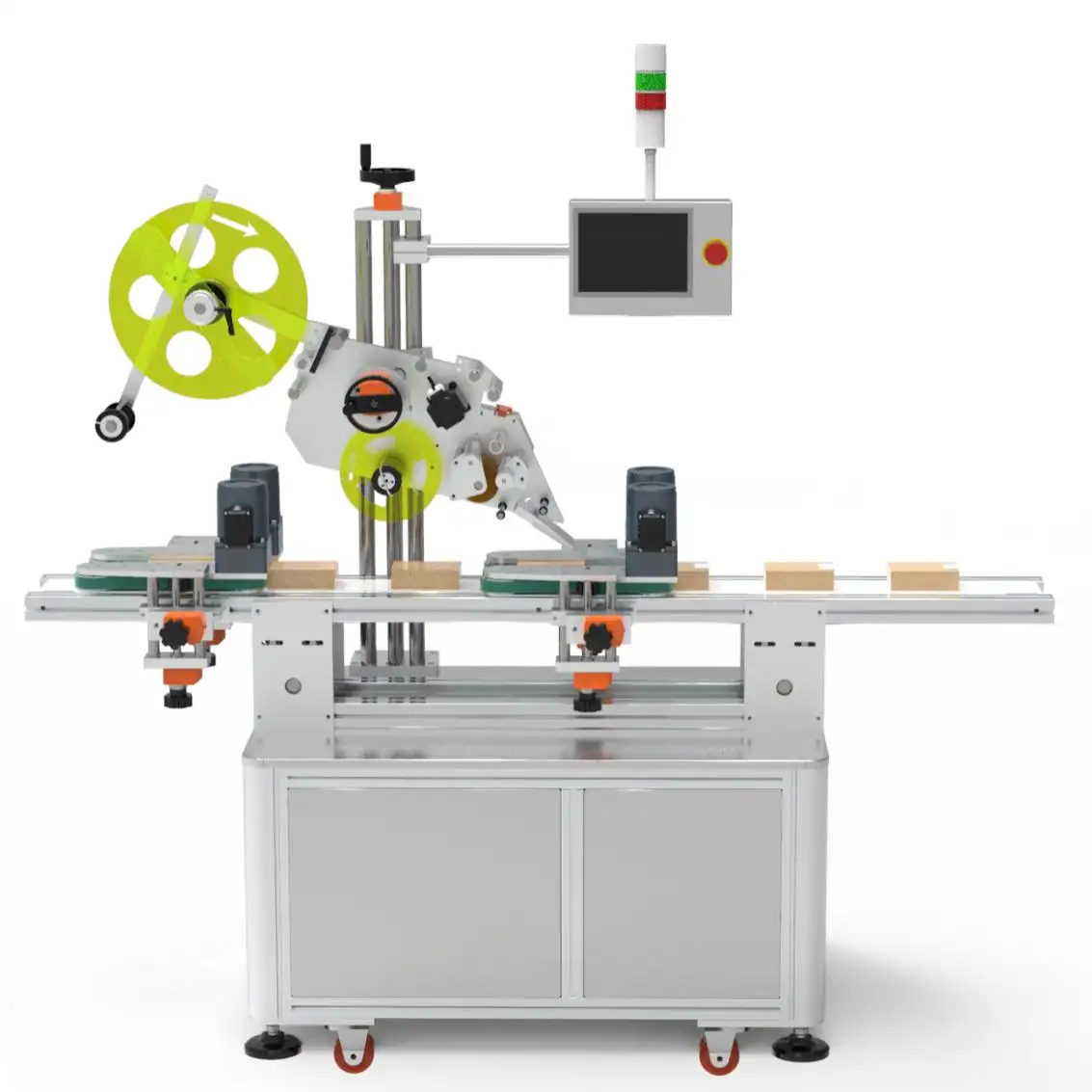

The maszyna do etykietowania płaskich butelek czasami nie komunikuje się poprawnie z drukarką. Może to prowadzić do problemów z drukowaniem etykiet. Oto kroki naprawcze dla błędu komunikacji:

Upewnij się, że drukarka jest podłączona i włączona.

Uruchom ponownie zarówno drukarkę, jak i maszynę do nadruku etykiet.

Przeczytaj od początku i upewnij się, że oprogramowanie do drukowania jest prawidłowo skonfigurowane z etykietami.

Wypróbuj wydrukowanie testowej etykiety, aby sprawdzić, czy wszystko działa.

Unikanie zagnieceń lub blaknięcia etykiet

Brudne lub chińska maszyna do etykietowania płaskich butelek nie prezentują się dobrze na produktach. Aby zapobiec temu na maszynie do nadruku etykiet, wykonaj następujące czynności:

Sprawdź, czy nie ma uszkodzeń lub zagnieceń na rolce z etykietami, które mogą powodować problemy.

Może być konieczne dostosowanie napięcia etykiet, aby umożliwić ich płynne przechodzenie przez maszynę.

Upewnij się, że etykiety są drukowane poprawnie, sprawdzając ustawienia drukowania.

Przełóż kilka produktów przez maszynę, aby sprawdzić, czy kształt etykiet jest ładny i gładki.

Te porady pomogą Ci utrzymać stan techniczny maszyny do etykietowania i zapewnić prawidłowe oznaczenie produktów. Ważne jest również upewnienie się, że maszyna jest zatrzymana i wyłączona w celu zachowania środków ostrożności przed dokonywaniem jakichkolwiek regulacji. Dobrą wiadomością jest to, że z niewielkim nakładem można uniknąć typowych błędów związanych z etykietowaniem i zachować estetykę produktu.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY