Bottle labeling is an essential part of your product packaging particularly if you are a company that sells beverages or any other type of liquid products. More so, with bottle labeling machines from companies such as SKILT, businesses are able to cut costs associated with labor. These apply bottles labels are fast and efficient, so you don’t require many person power to bottle labeling. This not only saves money but also helps businesses maintain the pace of increasing demand for their goods. Through the use of labeling machines, companies are able to focus in on improving their products versus worrying about how many workers they have going out on the floor just for labeling.

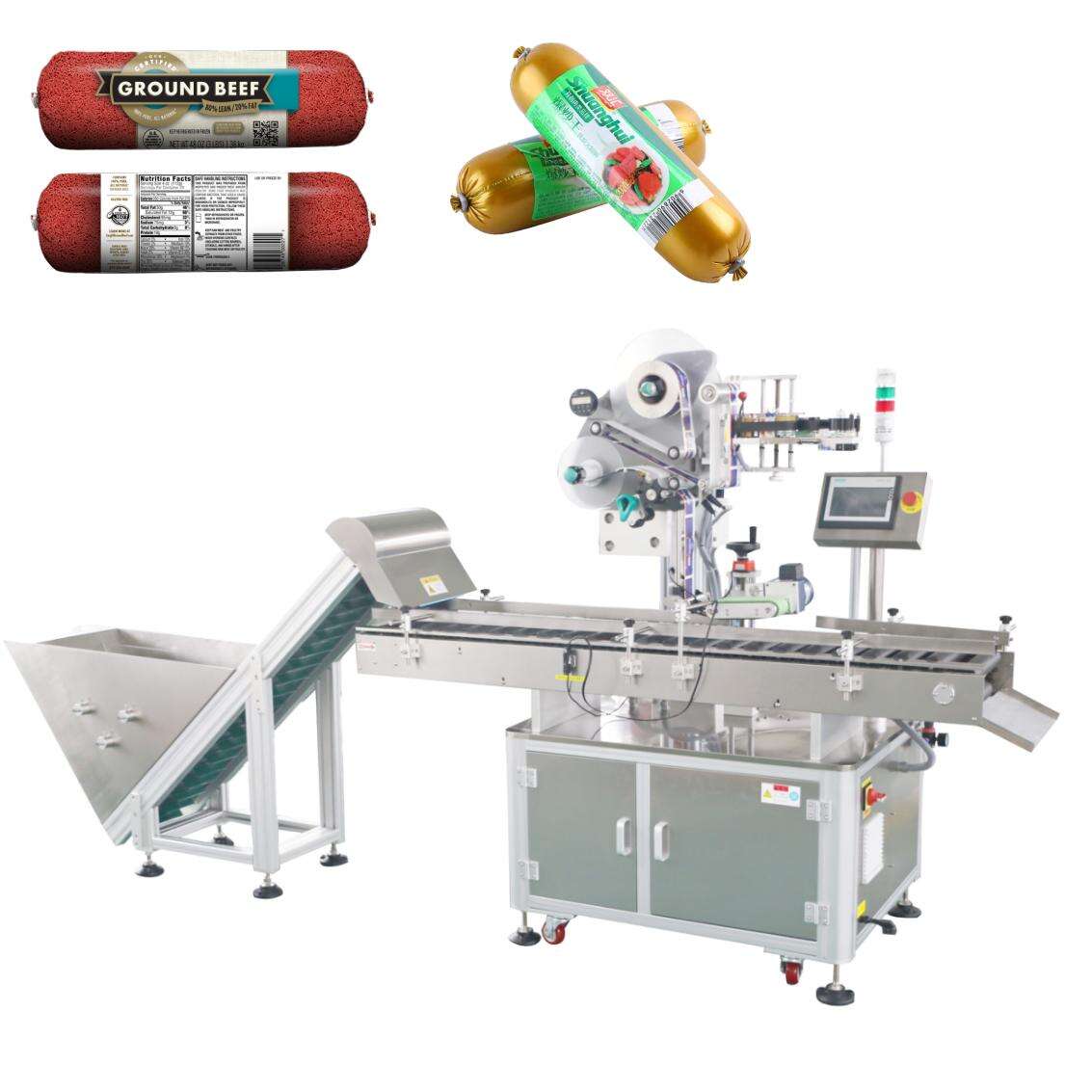

Food & Beverage Bottle Labeling Machines

When wholesale buyers are searching for products, they often want something with a high quality and great packaging. By utilizing bottle labeling machines, companies have the option to make each bottle look alike and that it will get labeled properly. This consistency is necessary because it creates a professional appearance to the products. When shop owners get drinks sent to them, for example, they want bottles that are clearly labeled and easy to read. It can leave the entire shipment looking shoddy if the labels are crooked or missing. With SKILT machines, hundreds or even thousands of bottles can be sticker in little time for any company. What this all means is that wholesale buyers receive their products in a timely manner and in better condition.

Furthermore, these machines are flexible to label various bottles and labels. This flexibility is an advantage for businesses selling multiple products. For example, a firm may produce water bottles and soda bottles. A labeling machine can be easily adjusted to dispense both of these closures, which means that you can achieve a dual purpose in one operation. It also lowers the opportunity for error, such as putting the wrong label on a bottle. This is very crucial as errors can result in disappointed customers and missed sales. With bottle labeling machines, these companies can streamline the process in a way that works well for everyone.

How Bottle Labeling Machines Increase Efficiency in High Volume Production

Speed and efficiency matter in factories where many bottles are made each day. With bottle labeling machines, businesses will be able to handle a high demand without having a whole lot of workers on staff. It is especially the case in busy times of year, like summer, when a greater number of people buy drinks. SKILT’s labeling machines enable business owners to label their bottles at a significantly faster rate than doing so by hand. A manual process may require hours to label a few hundred bottles, while machines can do the same job in minutes. This allows companies to make more, and satisfy customer demands rapidly.

And we even take advantage of labeling machines, so that the workers can concentrate on other activities. And instead of having to spend time labeling, they can taste quality control the drinks or be packaging for shipment. This re-purposed focus can pay dividends for everything that follows. It also means fewer workers are required to staff the label line, saving companies in hiring and training costs. It’s a big help for businesses that need to control expenses.

Super consistency is also crucial for high-volume manufacturing. Machines can apply labels consistently from one bottle to another, which is good for keeping a brand’s image consistent. If a company’s labels are attractive and don’t fall off, then it can create good will, as they say. With the bottle label applicators produced by SKILT, your company can make sure that all of your products are in line with high quality standards, which leads to happy customers who come back for more.

What to Find in Good Bottle Labeling Machines?

When in the market for a bottle label, there are certain aspects of the machine you should focus on finding to make sure it not only runs smoothly, but is specially tailored for your needs too. And you would, first of all, look at the speed of that machine. A desirable labeling machine is capable of filling most bottles quickly and easily. This way, you can fill your items faster and get them prepared for customers without wasting time. A further interesting aspect is the possibility of labeling of various formats of bottles. A few machines can apply labels to round bottles, and some may be compatible with square or oval ones as well. This flexibility also works well for companies featuring multiple products in a variety of bottle shapes.

Second, take into account how easy the machine is to operate. A good labeling machine from a place like SKILT will be made to have straightforward controls that any user can figure out immediately. That helps workers label bottles with little training. It should also be simple to clean and maintain. Which should leave you with plenty of spare hours, as you won’t need to spend too much time on repairs or cleaning duties.

Also take into consideration the size of the machine. If you’re low on space back in your packaging area, find compact machines that will lay out well without filling your space. Finally, consider whether the machine can accommodate varying label types and sizes. A versatile machine can also help to save you money as it enables you to use different types of labels rather than being confined just to one. Once you’ve got access to a bottle labeling machine with all these benefits, you can decrease labour costs, improve efficiency in your packaging line and much more.

Where to Purchase Dependable, Affordable Wholesale Bottle Labeling Machines

Purchasing bottle labeling machines in bulk can save your business money. Below is just a handful of places where you can get sturdy machines that fit your wallet. One of the best places to begin is online. A number of companies, like SKILT for one, have sites where they sell the machines to customers directly. When you purchase online, it’s easy to compare products and prices. Be sure to check customer reviews to get feedback on others’ experience with the machines. This will ensure you’re spending your money on a machine that works well and is worth the money.

You could also participate in trade shows or industry events. These functions draw numerous vendors displaying their new machines. You can see the machines in operation and ask questions of the sellers personally. This provides a good opportunity for you to do some research on the machines and get the best price. Sometimes you can also get special discounts at these bazaars.

You may even contact local selling bottle labeling equipment suppliers or dealers. They might have good deals or be able to direct you to a machine that is suited for what you need. While shopping for wholesale machines, be sure to inquire about warranties and customer support. You also want a machine from a reputable supplier, so it can help you if you get stuck after buying the machine. By looking at these various choices, you can easily locate an inexpensive, top quality bottle labeling machine for your business.

Advanced Technology in Bottle Labeling - Waking Up the Sleeping Giant

If you want to improve the efficiency of your packaging operations, then you simply cannot do so without advanced bottle labeling technology. One of the most effective ways to achieve this is by purchasing high-speed labelling machines from SKILT. These machines are able to label bottles at high speeds, which will allow you to get your product packaged in over a short amount of time. With a fast machine, your workers can stay focused on other critical operations, such as filling and sealing bottles, instead of sitting around while they wait for labels to be applied. This has a knock on effect of increasing the overall throughput of your packing line.

You could also improve efficiency using machines that can interface with other equipment in your production line. For instance, some smart labeling machines can also connect lines with filling machines and packing machines. This means they can start or stop automatically depending on the level of production carried out by other machines. Coordination like this can save time and streamline the whole process.

It will also be important to train your staff on how to properly operate the systems for the labeling machines. Proper training can help workers learn how to use the machines properly and take care of them. It’s a way to minimize the possibility of human error and keep machines at peak productivity.

Lastly, ensuring that you’re consistently taking care of your label machine is key to keeping them functioning properly. Arrange for regular maintenance and repairs to prevent days off due to surprised breakdowns. If you take care of your machines, they’ll be more effective and last longer which could actually save you money over time. With the right mix of technology, machine and line communication and machines that are properly trained and maintained, you can dramatically increase productivity in your packaging facility.

Table of Contents

- Food & Beverage Bottle Labeling Machines

- How Bottle Labeling Machines Increase Efficiency in High Volume Production

- What to Find in Good Bottle Labeling Machines?

- Where to Purchase Dependable, Affordable Wholesale Bottle Labeling Machines

- Advanced Technology in Bottle Labeling - Waking Up the Sleeping Giant

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV CA

CA TL

TL ID

ID LV

LV LT

LT SR

SR VI

VI ET

ET HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA MK

MK KA

KA BN

BN UZ

UZ KY

KY